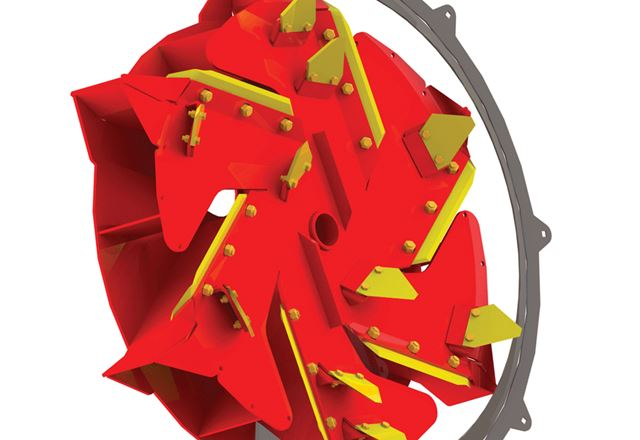

Teagle Tomahawk Drum Series

Chop and feed bales of silage, alongside barriers or into ring feeders, allowing greater intake of silage with less wastage. The Tomahawk Drum models are economical, simple and robust. There are no gearboxes, with the drive to the rotor being direct from the tractor, a hydraulic motor is used to rotate the drum. Due to their simplicity and strength, customers can expect a long service life from their Tomahawk.

Variants

Teagle Tomahawk Drum & Rotor Variants

4040 - Shred Hay or Silage

5050 - Shred Hay or Silage

5050XL - Shred Hay or Silage

505M - Mill Rotor (Dry Material)

505XLM - Mill Rotor (Dry Material)

Configurations

4040 - Suitable for 1.2m (4') diameter bales.

505M & 5050 - Suitable for 1.5m (5') diameter bales.

5050XL & 505XLM - Suitable for 1.5m (5') diameter bales and full-size Hesston bales.

Also available with electric drive (500E) or rear hydraulically angled slide (505FSM)

Operation

Blow straw up to 35', discharge to one or both sides of the tractor. Alternative delivery chutes are available to suit your requirements. Discharge silage to the right-hand side only into a ring feeder or along a feed barrier.

The Tomahawk 4040, 5050 and 5050XLM Bale Processor models use blades to chop dry or wet material. With very wet material the chop length may be as low as 4cm, and dry material will be around 15cm long.

Easy control of output by adjusting the speed of the drum rotation.

Overview

The Teagle Tomahawk 4040, 5050, and 500XL are industry-leading bale processors designed to meet the diverse needs of modern farmers. With their durable construction, versatile capabilities, and user-friendly design, these machines provide efficient solutions for processing straw and hay bales into manageable materials for livestock bedding, feeding, or mulching. Whether you’re a small-scale farmer or managing a large operation, the Tomahawk range offers reliable performance and high productivity to optimize your farming practices.

Easy Loading

Netting or wrap is easily removed at a safe working height. Adjustment of the drum angle with the optional hydraulic top link makes the operation even easier.

Direct Drive

Direct drive from shaft to rotor - no gearbox.

Chute On/Off Levers

Chute on the left and right-hand sides can be opened and closed independently.